- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

4-yob yob kom muaj zeb

Xa lus nug

Kub & Txias Rolling Plaspable

High-precision Multi-Batch Dov Solutions

Saj zawg zog tandem cov kab ntau lawm rau kev tsim khoom siv

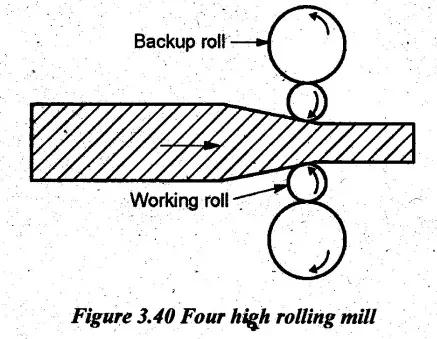

Grm 4-yob yob yob tau Mill Series tau siv dav hauv cov hlau thiab tsis muaj kev lag luam hlau rau nws lub siab-precision dov thiab ruaj khov thiab ruaj khov thiab ruaj khov nto.

Piv nrog rau grm ob-yob zeb, plaub-yob zeb tuaj yeem tswj cov tiaj tus ntawm sawb, txo cov khoom deformation, thiab yog li txhim kho cov khoom raug.

• Multi-Stand Configuration: Muaj peev xwm ntawm kev npaj Tandem nrog 2 txog 7 sawv ntsug, ua rau muaj peev xwm ua tau zoo dua qub.

• Ntau yam khoom sib xyaw: txhawb nqa hloov ntawm cov hlau txias thiab kub kub rau cov hlau, stainless hlau, thiab cov hlau uas tsis muaj hlau.

• Precision yob tswj kev tswj: tau tuab tuab tuab tuab tuab tuab siv qhov tseeb ntawm ± 0.003mm, ntsib High-batch rolling yuav tsum tau ua.

• Muaj peev xwm ua tau dav dav: pab ntsuas ntsuas dav ntawm 50 txog 450mm, nrog lub zog yob ntau ntawm 1200NSING RACKING APPTIONS.

Cov ntsiab lus zoo

• Ntau thiab cov kev sib koom ua ke kub & hloov pauv sai sai kom phim cov khoom.

• Riping Rolling Rolling System: Chaw-txuag tus qauv nrog cov lus pub rau kev noj haus kom ua haujlwm txuas ntxiv.

• Txawj Ntse Tswj Xyuas: Dual Servo Ntsia Hlau-Down & Hydraulic Roll hloov rau tsawg tsawg downtime.

Cov Ntawv Thov

| Tshav pob | Xwm txheej |

| Kev lag luam hlau | Kev tsim cov kub-rolled thiab txias-rolled carbon hlau strips |

| Tsis-Ferrous Hlau Ua | Cov Khoom Muaj nqis Hlau Strips (E.g., Titanium, Nickel Alloys) |

| Hluav taws xob thiab kev lag luam hluav taws xob | Kev tsim cov lithium roj teeb hluav taws xob (piv txwv li, txhuas ntawv ci, tooj liab rolling) |

| Automotive thiab Aerospace Kev Lag Luam | Kev tsim khoom ntawm lub teeb yuag txhuas thiab cov ntawv loj hlau nplaum |

Kev Ua Tshwj Xeeb

| Chaw ua uas tsis tau haus | Kev qhia tshwj xeeb |

| Khoom | Tooj liab, hlau stainless, carbon alloy |

| Cov menyuam cov pa hla | 40-320 hli |

| Max. Dov Force | 1200kn |

| Dov Ceev | 1200 m / m |

| Kev Nkag Tickness | 15-20 mm |

| Tawm tuab | 0.5-2.0 hli |

| Tuab ntaus | ± 0.03 hli (colding dov) |

Nco tseg: Cov teeb meem saum toj no yuav hloov pauv vim kev txhim kho cov khoom lag luam txuas ntxiv; Thov saib rau txhua cov khoom lag luam rau cov lus qhia tseeb.

• Induction Cua Sov Qaws: Kev tswj qhov ntsuas kub kom meej rau cov kev tswj kom muaj zog ntau ntxiv

• coiler nthuav tawm module: customized rau cov neeg yuav tsum tau ua

• Kev lag luam 4.0 interface: iot-enabled analytics

Vim li cas thiaj xaiv peb?

• Kev Txhawb Thoob Ntiaj Teb: 24/7 Cov Kev Pab Chaw Taws Teeb

• Ntawv pov thawj: CE, ISO 9001 ua raws

• Txiav kho cov kev daws teeb meem: khoom siv-tshwj xeeb dov profiles & nro tswj

Tiv tauj peb rau kev daws teeb meem customized

Email:solutions@grm-machinery.com

PERHAUG FAJ TIM RAU KEV RAUG - GRM MILLS REDEFINE CEEV CEEV DISRING